Automation Solutions

With our advanced technologies, extensive products and solutions and complete lifecycle services, we aim to enhance project certainty and operational reliability to help you become a benchmark enterprise.

The Pigging System also known as Pipeline Cleaning System or Product Recovery System, utilizes a slightly larger-diameter, flexible projectile called a "Pig" or "pipeline cleaner". This pig is propelled through the pipeline by water, other liquids, compressed air or gas, or even the product being processed, effectively removing or recovering residual product.

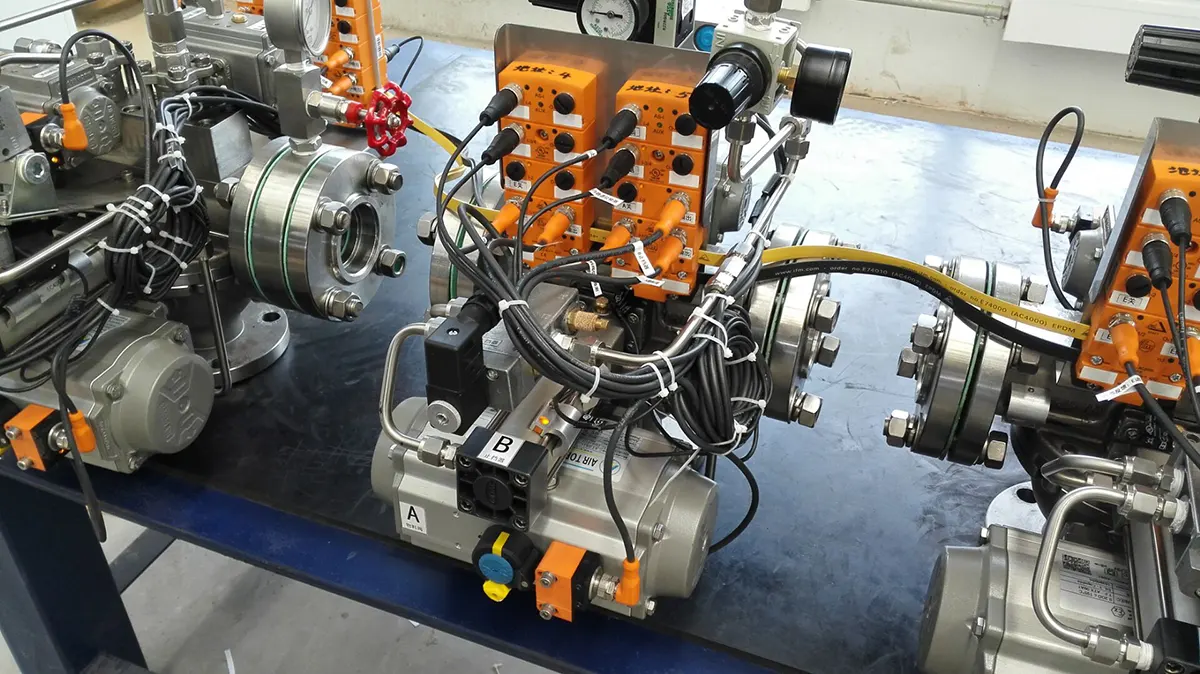

Pigging systems are categorized into several types, including Economic Pipeline Cleaning Systems, Sanitary Pipeline Cleaning Systems, and Sterile Pipeline Cleaning Systems. Additionally, these systems can be customized to meet specific product and customer requirements, offering fully automatic, semi-automatic, or manual options. BJVP provides a comprehensive suite of pipeline cleaning system components (launch stations, receiving stations, and pigs) and complete turnkey solutions.

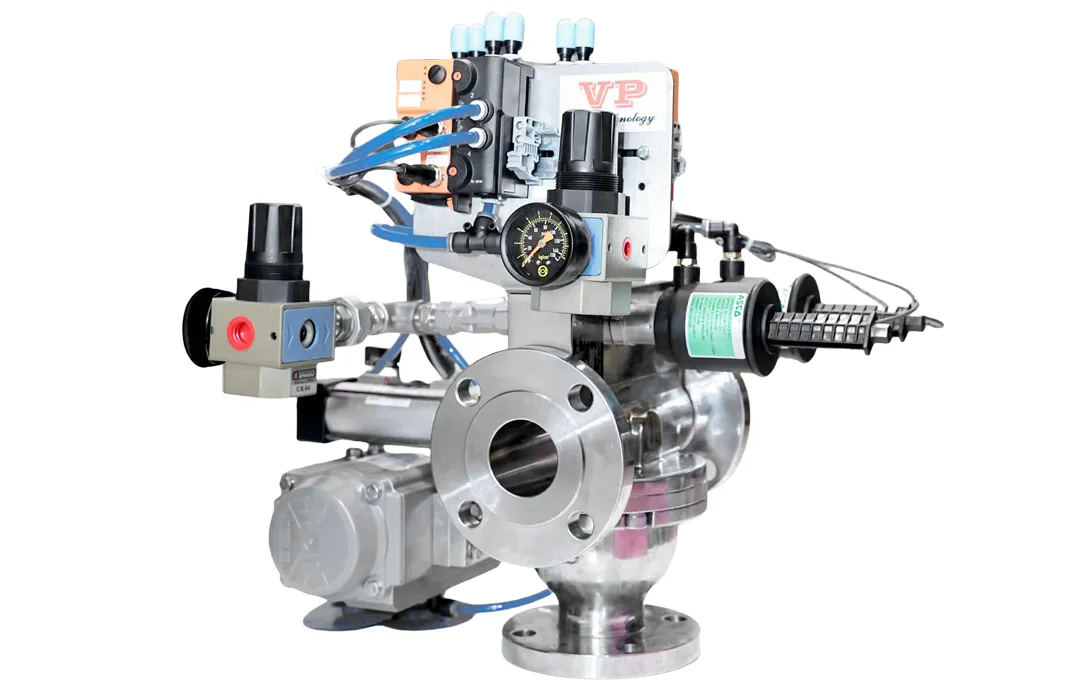

VP Pigging System is a technology of removing the liquid in the pipe through pigging. The PIG launcher and receiver are located at the both ends of the pipe, installed with a valve that controls the compressed-gas for receiving and sending of the PIG. The PIG can be put in or taken out by installing a catcher.

BJVP's Pigging System are widely applied across various industries, such as petrochemical, food (sauces, hot pot bases, chocolate, oyster sauce, doubanjiang, etc.), beverages, pharmaceutical liquids, dairy products, consumer goods (toiletries, cosmetics, detergents, laundry liquids, etc.), pet food, paints and coatings, and new energy lithium battery slurries.

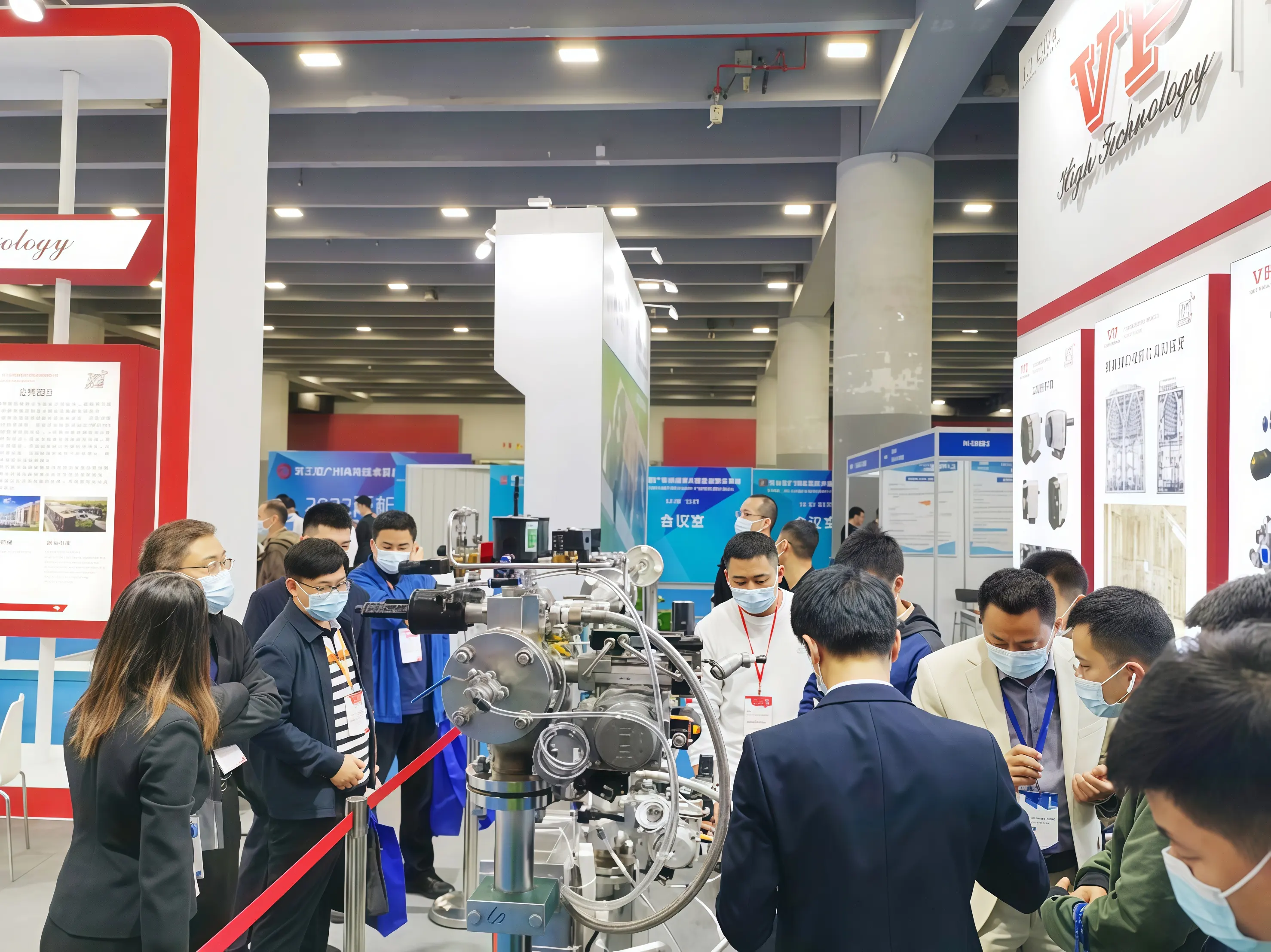

BJVP's Pigging System Exhibition at The 24th China Import and Export Fair (Canton Fair) is a showcase of our innovative technology in pipeline maintenance and efficiency.

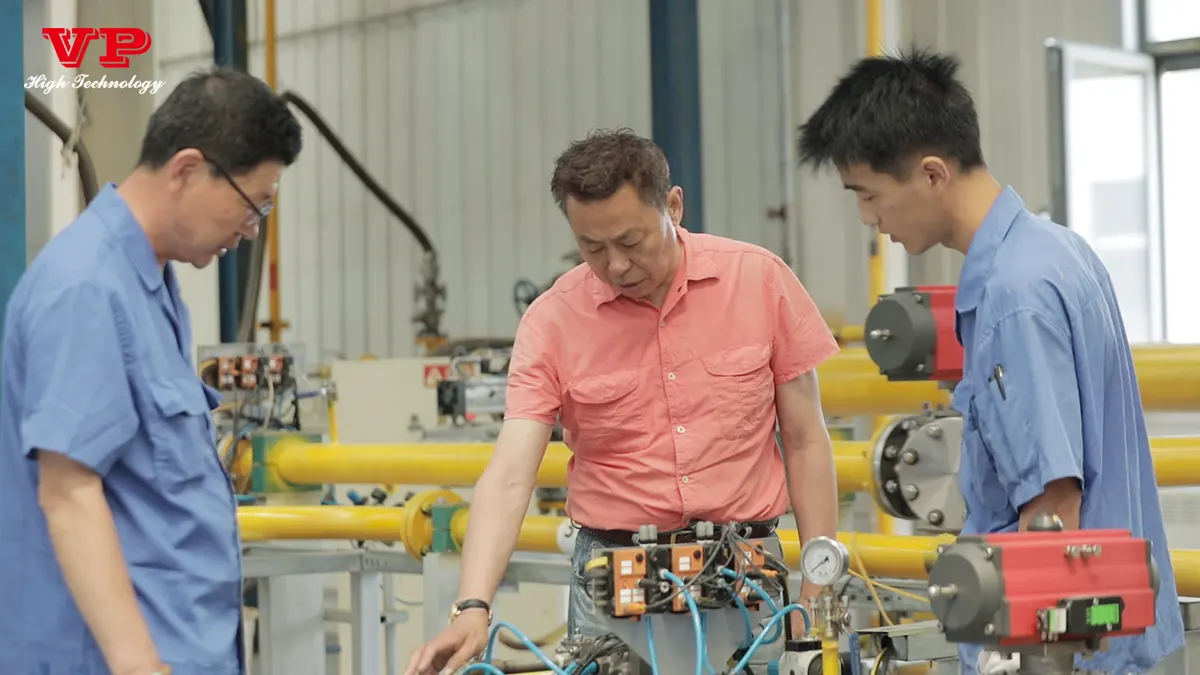

As a leading manufacturer in the Pigging System industry, BJVP is committed to delivering high-pressure pump solutions that are simple, reliable, and designed for long-term, trouble-free operation. Our exhibition highlights how our systems address the challenges of high-head, low-flow applications, effectively filling the gap where high-speed pumps and multi-stage centrifugal pumps fall short.

At the fair, visitors will discover that our Pigging System requires only a single impeller stage, simplifying the installation process to be on par with that of a standard centrifugal pump. Our system eliminates the need for auxiliary sealing and speed increaser lubrication systems, making it low-maintenance and user-friendly. BJVP's Pigging System is not only easy to operate but also robust and durable, with minimal wear parts, ensuring a reliable performance for our clients.

The advantages of VP Pigging System: High-efficiency self-cleaning pipeline, reduce pipeline material residue, cross contamination of materials, a variety of materials to share the pipeline to save space and cost.

BJVP Hygienic Pigging System use sanitary grade materials on contact surfaces.

Parameters

1. finishing pipe Pigging system: size 1.5” ~8”.

Includes launcher and receiver(Ashldv/Asrldv), intermediate stations (Asildv), three way reversing station(3W), PIG(Split type), PIG catcher.

2. Standard PIG catcher size: 8” and above.

Includes PIG catcher, three way receiver, valve and PIG.